滚珠丝杠的推力和转速有什么关系? 滚珠丝杠是什么? ,1. 宣城消磁滚珠丝杠是什么东西? ,9. 有哪些需要注意的使用注意事项?,7. 该直径是否需要定期检验和维护?,4. 这种滚珠丝杠的生产工艺是怎样的?,1. 什么是滚珠丝杠? ,10. 昭通滚珠丝杠升降机的售后服务如何?,4. 该厂家的客户群体有哪些?,10. 如何避免在重新组装滚珠丝杠时出现问题?,10. 滚珠丝杠左旋右旋的发展趋势是什么?

滚珠丝杠的推力大小与许多因素相关,包括滚珠丝杠的直径、螺距、滚珠数量、负载及润滑等等。因此,不能准确地回答“滚珠丝杠1nm推力多大”的问题。需要提供更多的具体信息才能回答这个问题。

相关问题:

What lubrication methods are used for ball screws and how do they impact performance?

伺服电机滚珠丝杠垂直连接是一种常见的机械传动方式,通常用于实现旋转运动和直线运动的转换。该连接方式通过将伺服电机和滚珠丝杠垂直安装在一起,使得电机的旋转运动能够转换为滚珠丝杠的直线运动,从而驱动机械系统实现工作。 具体实现时,伺服电机通常通过联轴器或直接连接方式与滚珠丝杠的输入轴连接在一起,通过电机的转动驱动滚珠丝杠的螺旋线轴向运动,从而实现工作负载的直线运动。该连接方式具有精度高、传动效率高、稳定性好等优点,在机械系统中得到广泛应用。What are the different types of ball nut designs and how do they affect performance?

Ball screw (滚珠丝杠) is a mechanical device that converts rotational motion into linear motion with minimal friction. It is widely used in various industrial applications such as machine tools, automation systems, and robotics. In this article, we will review some of the key aspects of ball screws and their design, operation, and applications. Design of Ball Screws Ball screws are designed to provide high accuracy and precision in linear motion applications. They consist of a screw shaft and a ball nut, which are both made of high-quality materials such as steel or stainless steel. The screw shaft has a helical groove or thread that runs along its length, while the ball nut contains a series of ball bearings that fit into the helical groove. When the screw shaft rotates, the ball bearings move along the groove, causing the ball nut to move linearly along the shaft. The design of ball screws is critical to their performance and durability. Factors that must be considered include the diameter and pitch of the screw shaft, the number and size of the ball bearings, the preload and clearance of the nut, and the type of lubrication system used. These parameters can be optimized to achieve the desired level of accuracy, speed, and load capacity. Operation of Ball Screws Ball screws operate by converting rotary motion into linear motion with minimal friction. This is achieved through the use of ball bearings, which roll along the helical groove of the screw shaft and the ball nut. The rolling action of the balls reduces friction and wear, resulting in high efficiency and long service life. Ball screws are typically driven by an electric motor or other power source. The speed and direction of the motor are controlled by a feedback system, which monitors the position and velocity of the ball nut and adjusts the motor accordingly. This allows for precise control of the linear motion and ensures that the ball screw operates within its rated capacity. Applications of Ball Screws Ball screws are widely used in various industrial applications, including machine tools, robotics, automation systems, and aerospace. They are particularly well-suited for applications that require high accuracy, precision, and efficiency. Some common examples include CNC machines, linear actuators, and positioning systems. In the aerospace industry, ball screws are used in aircraft control systems, landing gear, and engine components. They are also used in satellite systems and other space applications, where reliability and durability are critical. Conclusion Ball screws are an essential component of many industrial systems, providing precise and efficient linear motion. Their design, operation, and applications are complex and require careful consideration of many factors. However, with proper design and maintenance, ball screws can provide reliable and long-lasting performance in a variety of industrial applications.

5. 材料问题:滚珠丝杠的材料如果出现问题,也会导致间隙过大,

总之,北京精密双向滚珠丝杠是一种高性能的传动元件,具有高精度、高负载能力、长寿命和平稳运行等特点,是机床、机器人、自动化设备等领域的理想选择,双鸭山直线导轨滚珠丝杠是一种机械传动元件,由导轨、滚珠丝杠和螺旋凸轮组成,单滚珠丝杠是一种机械元件,由螺杆和螺母组成,注意不要损坏其他机床部件,

2. 可以承受大的负载和惯性力,具有高刚性,

5. 沿着直径的两端分别画出两条弧线,表示滚珠的表面,如有异常,请重新安装或更换轴承,

如果您发现滚珠丝杠变色,可以先用清洁剂将其表面清洗干净,以消除油污的影响,

2. 精度标准化:精密滚珠丝杠的精度需符合国家标准或行业标准,如GB/T 1184-1996《螺纹》等

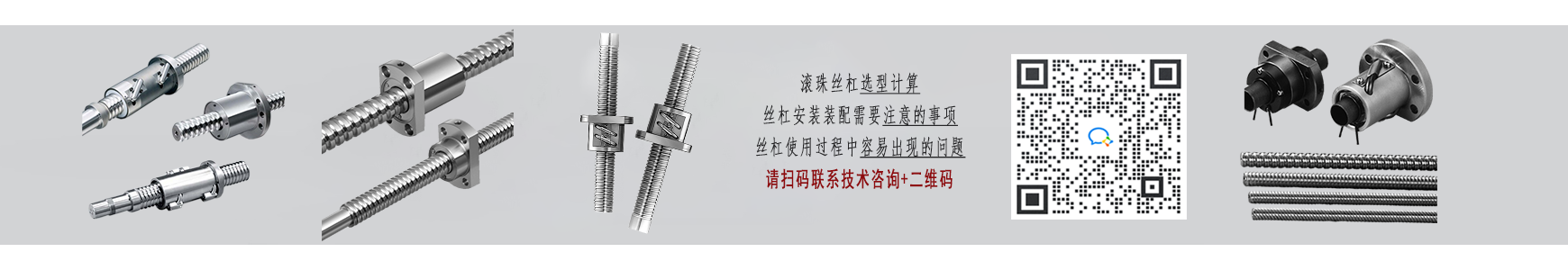

请扫码获取更多信息

推荐阅读

什么是滚珠丝杠热分析?

2023-06-24

薄壁滚珠丝杠的使用方法是什么?

2023-06-24

什么是滚珠丝杠的螺旋角度?

2023-06-24

滚珠丝杠的螺母的作用是什么?

2023-06-24

测试的重要性在哪里?

2023-06-24

滚珠丝杠在机械制造中扮演着什么角色?

2023-06-15

这家厂家的生产能力如何?能否满足大批量订购?

2023-06-12

什么是滚珠丝杠?

2023-06-09

What are the most common failure modes for ball screw bearings, and how can they be prevented?

2023-06-09

选型的目的是什么?

2023-06-06